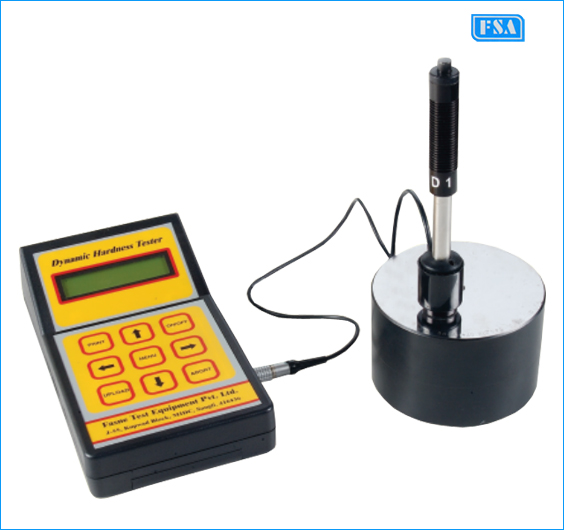

• Sleek & handy design, comes in a slim briefcase, for carrying the machine.

• Mainly used to check hardness in confined spaces, on large & heavy components, permanently installed parts with

low test expenditure.

• The machine has built in conversion facility for given material to convert ‘D’ value to Vickers (HV), Rockwell

(HRB, HRC), Brinell (HB), UTS scales which can be selected by pressing arrow keys.

• The model operates on two numbers of pencil cells.

• 30 hardness scales for different probes selectable by feather touch keys.

• Alpha numeric display – 16 characters x 2 lines LCD with improved electronics, micro controller circuity & user

friendly

• software. Display indicates selected material & scale combination & hardness value.

• Five numbers of probes D, G, SH, EX & C can be given in different combinations.

• Facility to connect dot matrix printer through centronics parallel port.

• Upto 100 readings can be stored in memory of the machine for printing purpose.

• Serial interface is possible with RS 232 port at an additional cost.

• Automatic calibration facility of probe is available through keyboard.

• Extra (Optional) Accessories such as – Standard test blocks, support rings, printer, serial interface, different types of

probes are available.

| HARDNESS / MATERIAL | TEST RANGE AND ORDER CODE | ||||

| BRINELL | VICKERS | ROCKWELL - C | ROCKWELL - B | SHORE D | |

| Steel and Cast Steel unalloyed /Low alloyed |

80 - 647 ST / BHN |

80 - 940 ST / VPN |

20 - 68 ST / HRC |

38.4 - 99.5 ST / HRB |

32.5 - 99.5 ST / HSD |

| High Carbon, High Chromium (12% & above) Cold Work tool steel | - | 80 - 898 HC / VPN |

20.4 - 67.1 HC / HRC |

- | - |

| S.G. Iron (CI with spheroided and nodular graphite) (GG-40-80) | 131 - 387 SG / BHN |

- | - | - | - |

| Grey Cast Iron Grade 15-40 (GG) |

93 - 334 CI / BHN |

- | - | - | - |

| Cast Al. Alloys non heat treated and quenched & tempered condition | 30 - 159 AL / BHN |

- | - | - | - |

| Copper Zinc Alloys (Brass) | 40 - 173 BS / BHN |

- | - | 13.5 - 95.3 BS / HRB |

- |

| Copper Al. and Copper Tin alloy (Bronze) | 60 - 290 BZ / BHN |

- | - | - | - |

| Wrought Copper Alloys (Low alloyed) | 45 - 315 Cu / BHN |

- | - | - | - |

| Stainless Steel& High temp. resistant Steel. | 85 - 655 SS / BHN |

85 - 800 SS / VPN |

19.6 - 62.4 SS / HRC |

46.5 - 101.7 SS / HRB |

- |

| HARDNESS / MATERIAL | TEST RANGE AND ORDER CODE | |

| BRINELL | ROCKWELL - B | |

| Steel & Cast Steel / Unalloyed and Low alloyed |

90 - 640 ST / BHN-G |

47 - 99 ST / HRB-G |

| Grey Cast Iron Grade 15 - 40 (GG) | 90 - 315 CI / BHN-G |

- |

| S.G. Iron (CI with spheroided and nodular graphite) (G.G - 40, 80) | 125 - 350 SG / BHN-G |

- |

| HARDNESS / MATERIAL | TEST RANGE AND ORDER CODE | |||

| BRINELL | VICKERS | ROCKWELL - C | SHORE D | |

| Steel & Cast Steel / Unalloyed and Low alloyed | 80 - 683 ST / BHN-C |

80 - 996 ST / VPN-C |

20 - 69.5 ST / HRC-C |

31.9 - 99.6 ST / HSD-C |

| Probes |

Standard (D) | Dia. 25 x 150 mm long. |

| Short (SH) | Dia. 25 x 100 mm long. | |

| Extended (EX) | Dia. 25 x 150 mm long. | |

| Heavy (G) | Dia. 30 x 255 mm long. | |

| Low energy (C) | Dia. 25 x 145 mm long. | |

| Digital Display Unit | - | 188 (L) x 105 (W) x 64 (H) mm. |

| Measuring Accuracy - Average Measuring deviation ±1% referred to D = 800 on Standard “D” Test Block at a particular test location |

||

| Weight (Approx.) - Probe (Standard) - 150 gms. Display Unit - 325 gms. ‘D’ scale standard test block - 3000 gms. Total Weight - 7 kg. of Machine (with all accessories & carry case) |

||

| Operating Temp. Range - 0°C to 50°C |

||

| FIELD | FOR D/SH/EX PROBE | FOR G PROBE | FOR C PROBE |

| Prepration of the surface to be tested | N 7 ( 66 ) | N9 | N5 |

| Max. roughness depth RL | 10 microns | 30 microns | 2.5 microns |

| Av. roughness depth Ra = Cla = AA | 2 microns | 7 microns | 0.4 microns |

| Min. weight of the test piece………. - of compact shape - on solid support - coupled |

5 kg. 2.5 kg 0.1 to 2 kg. |

15 kg. 5-15 kg 0.5-5 kg. |

1.5 kg. 0.5-1.5 kg 0.02-0.5 kg |

| Min. thickness of test piece coupled | 5 mm |

15 mm | 2 mm |

| Min. thickness of layer with surface hardening | 0.8 mm | - | 0.2 mm |

| Indentation of the test tip with 300 HB specimen…………… Hardness - Diameter Depth |

0.6 mm 13 micron |

- | - |

| Min. bore dia. of the specimen (only for short probe) | 100 mm | - | - |

With standard support ring machine can work on a minimum radius of 60 mm convex or concave. For lesser job dia. suitable additional support rings can be provided. (Ref. Extra accessories).

Power Supply Conditions

Dry cell batteries (1.5 VDC x 2 Nos.) ; Size - AA, Type - R6.

Standard Accessories

• Probe (Normally ‘D’, if specified other ProbeCan be supplied in place of ‘D’) - 1 No.

• Digital display unit - 1 No.

• Standard test block calibrated in ‘D’ Scale - 1 No.

• Brush for cleaning probe - 1 No.

• Carry case for Machine - 1 No.

• Instruction manual - 1 No.

• Coupling Jelly - 50 gms.

Extra (Optional) Accessories

Standard Test Block of any hardness.

Support rings for smaller radius for -

• (SR 1) Convex, Concave, Cylindrical, Spherical radius 30 to 60 mm

• (SR 2) Convex cylindrical radius 14.5 to 30 mm

• (SR 3) Convex cylindrical radius 10 to 15 mm

• (SR 4) Concave cylindrical radius 16.5 to 30 mm

• (SR 5) Concave cylindrical radius 12.5 to 17 mm

• (SR 6) Concave cylindrical radius 11 to 13 mm.

Serial Interface (Windows 98 Based).

80 Col. Dot Matrix Printer.

Different types of Probes -

• Standard (D)

• Short (SH)

• Extended (EX)

• Heavy (G)

• Low Energy (C)